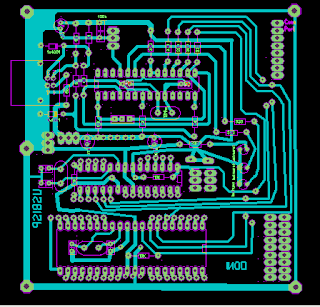

Project 21 vga breakout Printed in PCBway.com

Huurreeyyy... My PCB has Arrived from China !!! lets unbox .my PCB p4xet.

vga breakout is Modul for General purpose connector VGA

Cheap but with nice quality. only $5 got 10 pieces.

I got design from internet, i forgot the link. simple unique design . great thickness 1,6mm with two layer. you can choose any color from green , red, blue, black , white and yellow. this time i select green silkmaskcolor. Next order... resise into duino std form brd

63.5mm * 57mm

Thickness:1.6 mm, 2 Layers,

Finished Copper:1 oz Cu

only US $5 recieve 10 pieces

Project No: W09439A SX21.

this desi9n uni9ue. text writen on copper l4yer. so it become resistence into few strecth m4rk. cause m4de from copper. ref src : i forgot .. try google search.

you m4y come bec to visit tis web for news upd4te :)

TOP Design :

ENIG vs HASL

"ENIG", which stands for "Electroless Nickel Immersion Gold". It consists of an underlying layer of nickel with a thin layer of gold over the top. The gold layer is very thin and not intended to provide the main structure of the track, it just acts as a protective coating for the nickel to prevent it tarnishing before it's soldered. Gold is extremely resistant to corrosion so ENIG has several good points: it can be touched with bare fingers without tarnishing, has a very long shelf life, and the pads / tracks are very flat and square-edged - something that can be important for fine-pitch surface-mount parts.

One one bad aspect to ENIG though is that it takes a bit more solder to complete a joint because the surface hasn't yet been pre-tinned, and because there isn't an existing layer of solder to melt against the iron and increase the initial contact area (hence increasing the rate of heat transfer) it can take an extra second or so to get the joint hot. You really need to make sure your iron has good contact with the joint to make sure enough heat is transferred to the track and the component lead.

HASL

The most common surface finish you see on PCBs is called "HASL", or "Hot Air Solder Levelling". HASL boards are dipped in molten solder and then the excess is cleaned off using hot-air knives to leave behind the thinnest possible layer of solder. The solder itself then protects the underlying track from corrosion while making it extremely easy to solder on parts, because the whole pad is pre-tinned. It's generally the cheapest finish available and a great choice for general-purpose boards. One downside to HASL is that even after the hot-air knife has cleaned off as much excess as possible, the meniscus of the solder will still cause the edges of pads to be slightly rounded. That makes surface-mount parts not sit down quite as flat as they would on an ENIG board.

Komentar

Posting Komentar